In this discussion, we will be focusing on the temperature mapping of storage areas, Good Manufacturing Practice (GMP) warehouse requirements, warehouse GMP checklist, WHO guidelines for warehouse temperature mapping, GMP warehouse audit fail, and how to write effective Standard Operating Procedures (SOPs) in Pharmaceuticals.

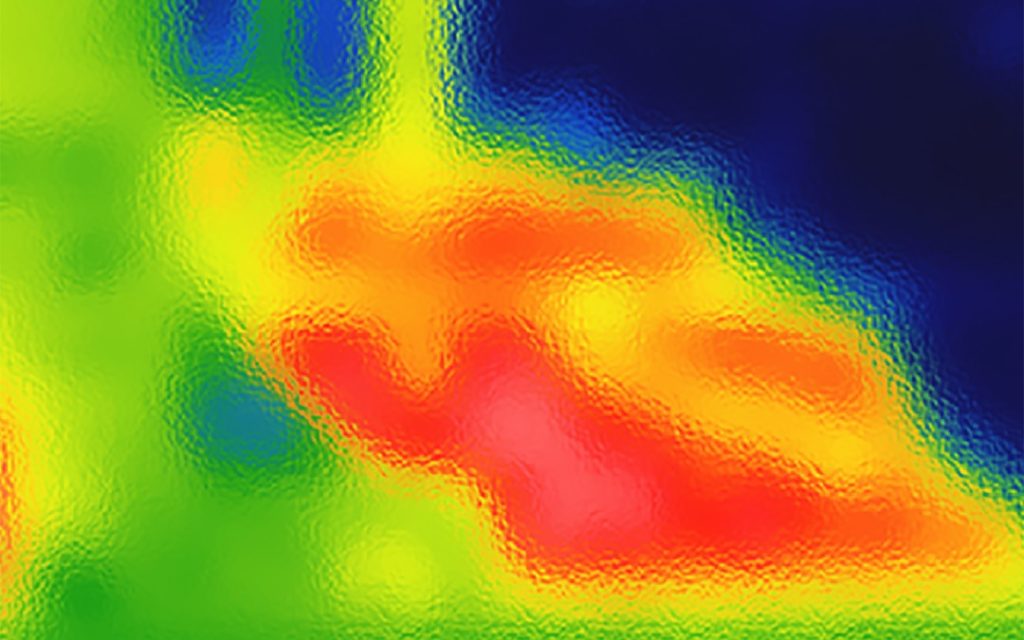

- Temperature Mapping of Storage Areas Interviewer: Can you explain what temperature mapping of storage areas is, and why it is important? Brij Suri: Temperature mapping is the process of measuring and recording temperature and humidity throughout a storage area to ensure that products are stored under the correct environmental conditions. It is important to ensure the quality and safety of products as certain pharmaceuticals, biologics, and medical devices can be sensitive to temperature changes.

- Interviewer: What are the GMP warehouse requirements, and how do they differ from standard warehousing practices? Brij Suri: GMP warehouse requirements are a set of guidelines and regulations that ensure that pharmaceutical and medical products are stored and handled in a safe and controlled manner. They differ from standard warehousing practices as they require specialized knowledge and training, as well as equipment and procedures that maintain the integrity of the products being stored.

- Interviewer: Can you provide an overview of what is included in a warehouse GMP checklist? Brij Suri: A warehouse GMP checklist includes items such as environmental control, pest control, cleaning and sanitation, inventory management, and documentation. These items ensure that the warehouse is compliant with GMP regulations and that the products being stored are being handled safely.

- Interviewer: What are the WHO guidelines for warehouse temperature mapping, and how do they differ from other guidelines? Brij Suri: The WHO guidelines for warehouse temperature mapping provide guidance on the temperature requirements for different pharmaceutical products and the methods for measuring and recording temperatures. They differ from other guidelines as they take into account the different environmental conditions in different regions of the world and the different types of products being stored.

- Can you explain what happens when a GMP warehouse audit fails, and what steps are taken to address the issues identified? Brij Suri: When a GMP warehouse audit fails, it means that the warehouse is not compliant with GMP regulations, and corrective action must be taken to address the issues identified. This can include retraining staff, upgrading equipment or procedures, and implementing new quality control measures.

- Interviewer: Can you provide some tips on how to write effective SOPs in Pharmaceuticals? Brij Suri: Effective SOPs in Pharmaceuticals should be clear, concise, and easy to understand. They should include step-by-step instructions, as well as any necessary safety precautions and quality control measures. They should also be regularly reviewed and updated to ensure that they remain current and relevant.

Our qualified team of professionals would love to talk to you about questions or any requirements. Talk to our team now using the contact button for questions or needs.

Contact Us Via WhatsApp Contact Us Via Email Call Us Via Phone